MPD solenoid at NICA was cooled down to operating temperatures

News, 20 December 2024

In December 2024, one of the main stages of commissioning the MPD solenoid at the NICA Accelerator Complex finished: the entire body of the superconducting coil of the solenoid was successfully cooled down to operating temperatures of 4.5-5 kelvins (-268.65 – -268.15 °C). This indicates the absence of so-called cold leaks and proves the quality of the development of cooling circuits and hydraulics.

The start of cooling was preceded by the assembly of all elements of the cryogenic system in the Laboratory of High Energy Physics at JINR without the participation of manufacturers, ILK and ASG, with some of the cryogenic equipment supplied by Russian companies.

VBLHEP JINR Deputy Chief Engineer Konstantin Mukhin explained that the very first cooling of the solenoid (down to liquid nitrogen temperatures of 80 K (-193.15 °C) took place in February and March 2024: “The initial cooling confirmed that there were no cold leaks at the nitrogen level and that the cooling scheme was working.”

After this, the specialists prepared the updated solenoid software. “This was closed source software, so apart from looking for passwords and the source, we had to add our own code. We designed completely new software for the MPD refrigerator, since the original German one did not allow for smooth valve control and was overall aimed at monitoring only,” Konstantin Mukhin said. Employees of Extended Range Systems LLC developed the refrigerator software. The control cabinet was completely redesigned, allowing adjusting the refrigerator systems more smoothly and in the modes required for operation. “We have managed to write the algorithms and are now refining them. In the near future, the refrigerator’s software will be automated, which will greatly facilitate the operators’ work and reduce the consumption of resources: liquid nitrogen and liquid helium,” he commented.

“In spring and summer, we refinemed cryogenic and technological equipment, installed the main nitrogen pipe (more than 100 m long), added temperature sensors to the superconducting cable, and finalised the system for maintaining the set nitrogen temperature. Given the lack of a main helium pipe (to be supplied from the INP), we have developed a new temporary scheme and started the cooling on 5 November. In 15 days, we reached the temperatures of liquid nitrogen and have since been working with a new operating mode, the temperature of liquid helium,” Konstantin Mukhin said.

As a result, the solenoid was completely cooled to the operating temperature of 4.5 K. Students from Saint Petersburg State University and Moscow Engineering Physics Institute worked shifts together with the VBLHEP employees during the cooling. The MPD team is automating the software modes, solenoid cooling analysis, and operation of the control Dewar and refrigerator systems. In addition, they are optimising the operation of the systems when moving helium tanks used to supply helium inside the refrigerator according to a temporary scheme. It is currently possible to change tanks without stopping the cooling process, which is highly important for maintaining operating temperatures in the superconductor during long operating cycles necessary for further tests when current is input into the coil.

“The next task is to check the protections and input current into the solenoid. By the end of December, we will try to gradually introduce a current of about 100 A and begin testing the protection system in case of superconductivity failure,” Konstantin Mukhin concluded.

In the last decade of December, the solenoid will be heated, and testing of power systems will take place from the end of the year to the end of January. From the beginning of February, MPD will be re-cooled to 4.5 K. Then, the VBLHEP employees will measure the magnetic field map of the solenoid for 2.5 months, after which everything will be ready for the assembly of the MPD detector systems.

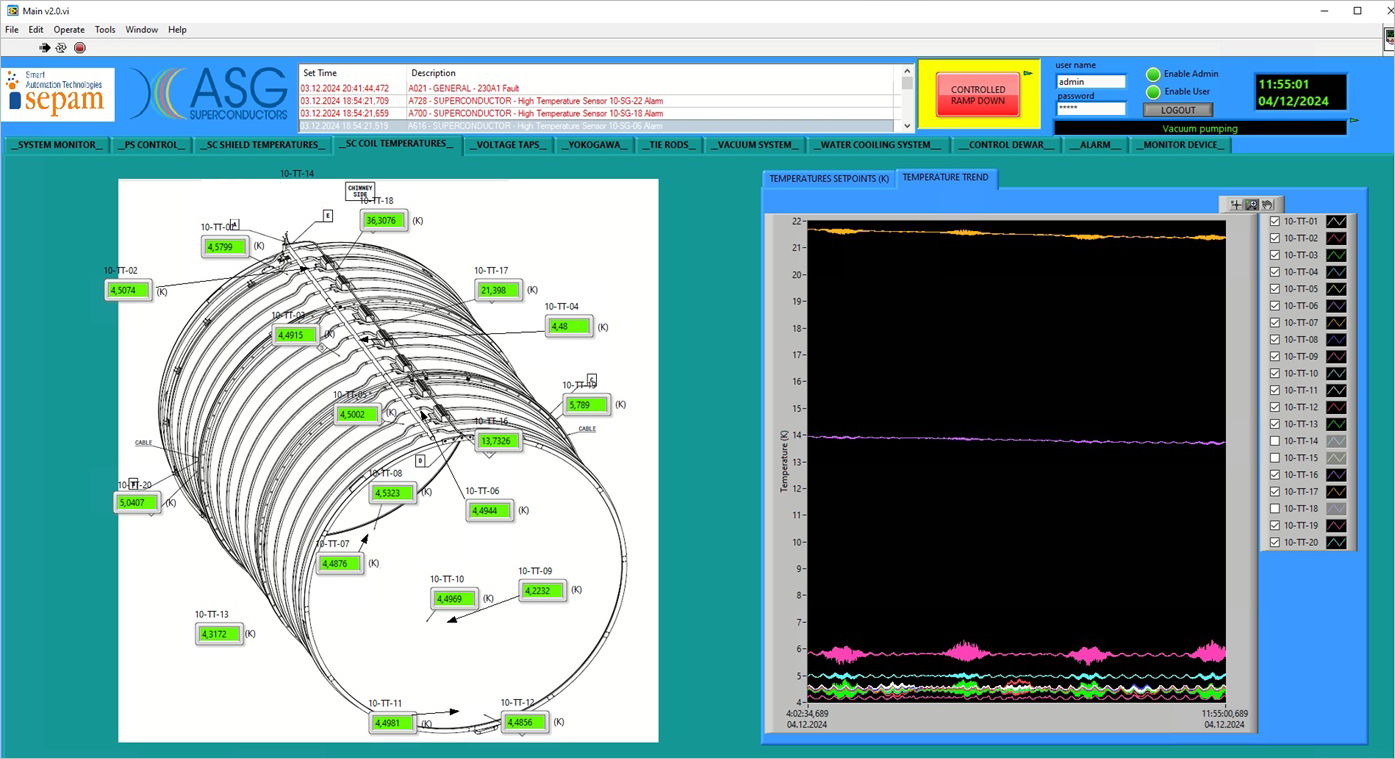

The figure with the readings of the temperature sensors installed inside the cooled coil was obtained using the control software. The cooling process continues according to plan. The figure shows that the cable in the upper part of the coil connected to the control Dewar has not fully cooled yet, but this is normal at this stage

The figure with the readings of the temperature sensors installed inside the cooled coil was obtained using the control software. The cooling process continues according to plan. The figure shows that the cable in the upper part of the coil connected to the control Dewar has not fully cooled yet, but this is normal at this stage