Device for controlling light transmission efficiency of optical fibres created at FLNP JINR

News, 10 October 2023

Specialists of the Frank Laboratory of Neutron Physics, JINR, have developed a device that makes it possible not only to detect defects in wavelength-shifting optical fibers, but also to control whether the material with these defects retains its main function – transmitting capacity. In other words, the new device allows one to understand how defects in fibers affect the loss of light transmitted through them. The patented device was used in the development of two large-area thermal neutron detectors for scientific instruments at the IBR-2 research reactor.

FLNP is engaged in the creation of scintillation wide-aperture high-resolution detectors of thermal neutrons. The design of a ring detector with a diameter of more than two meters involves the use of several kilometers of wavelength-shifting optical fiber to collect light from this vast surface. The detector material absorbs neutrons, resulting in scintillation (glow for a fraction of a second), which is transmitted via optical fibers to photomultiplier tubes (PMTs), where it is converted into an electrical signal, which is then processed using analog or digital electronics.

“Optical fiber is a technologically complex material that absorbs light, re-emits it, and, due to the effect of total internal reflection, transmits it over long distances,” said Maxim Podlesnyy, co-author of the invention, junior researcher at the Department of the IBR-2 Spectrometers’ Complex (FLNP JINR). He explained that optical cables are supplied to the Laboratory in large rolls, which inevitably contain defects in some places: damages of the outer layer, fractures, bends, as well as bubbles inside fibers.

Fig. 1. Photos of various damages in optical fibers (from left to right): 1 – bubble; 2 and 3 – external mechanical damages; 4 – fracture

Fig. 1. Photos of various damages in optical fibers (from left to right): 1 – bubble; 2 and 3 – external mechanical damages; 4 – fracture

Using the new device, it was determined how different types of defects weaken the transmitted light signal. “When designing a particular type of detector, it is necessary to determine which fibers can still be used and which cannot. Provided that defects weaken the signal by no more than 5-10%, and also provided that the light is collected not by one fiber, but by several fibers for one detection channel, the fiber can be considered usable,” commented Maxim Podlesnyy. During the measurements, the following statistical data were collected:

Table 1. Effect of fiber damage on its properties

| Type of damage | Deviation from the signal amplitude of undamaged fiber |

| Bubble | < 5 % |

| External mechanical damage | 10–15 % |

| Fracture | > 20 % |

For example, a fiber with bubbles is suitable for further use, but its fractured section is not.

The technologies mastered by FLNP specialists for creating neutron detectors based on 6LiF/ZnS(Ag) scintillators have opened up opportunities for developing wide-aperture detectors of thermal neutrons. The ASTRA-M detector has been designed and constructed for the FSD Fourier stress diffractometer, and a wide-aperture backscattering detector for the HRFD high-resolution Fourier diffractometer is at the final stage of development. These scientific instruments are intended for the study of internal stresses in structural materials and precision analysis of the crystal structure of samples. The high-resolution detectors of these diffractometers are designed on the principle of geometrical time focusing during diffraction, with their sensitive area reaching 13.8 sq.m. The development and construction of detectors require solving a number of technological problems, one of which is studying the quality of supplied optical fibers. “Our device allows us to test the quality of fibers of different lengths under the same conditions: the ends of the fiber are equally fixed relative to the input window of the photomultiplier and LED by means of movable fixing mechanisms,” the scientist noted.

Fig. 2. Internal part of the device: 1 – guides; 2 and 3 – fixing elements; 4 – system fixing element; 5 – auxiliary fixing elements; 6 – LED; 7 – signal transmission wires

Fig. 2. Internal part of the device: 1 – guides; 2 and 3 – fixing elements; 4 – system fixing element; 5 – auxiliary fixing elements; 6 – LED; 7 – signal transmission wires

Fig. 3. General view of the measuring system: 8 – photomultiplier housing; 9 – photomultiplier; 10 – signal pickup cable from the photomultiplier; 11 – voltage pulse generator; 12 – signal transmission cable for the generator; 13 – light-insulating housing; 14 – oscillograph

Fig. 3. General view of the measuring system: 8 – photomultiplier housing; 9 – photomultiplier; 10 – signal pickup cable from the photomultiplier; 11 – voltage pulse generator; 12 – signal transmission cable for the generator; 13 – light-insulating housing; 14 – oscillograph

The light-isolating housing of the device consists of two interconnected parts: the photomultiplier housing and the housing of the internal part of the device. The internal part comprises two guides fastened by the non-movable end fixing elements. The first one fastens the end of the wavelength-shifting optical fiber on the surface of the input window of the photomultiplier, and the second contains a connector on the part external to the housing, to which the electrical pulse generator is connected by a cable. The internal part of the measuring facility contains fixing elements that move along the guides depending on the length of the optical fiber. There are two types of fixing elements: auxiliary fixing elements located along the optical fiber, and a system fixing element with a hole for fastening the end of the optical fiber and transmitting light into the light guide. There is an LED on the system fixing element. The signal transmission wires are spring-wound around the free part of the guides. The device measures the amplitude of an optical wave after passing through a wavelength-shifting optical fiber for fibers of different lengths.

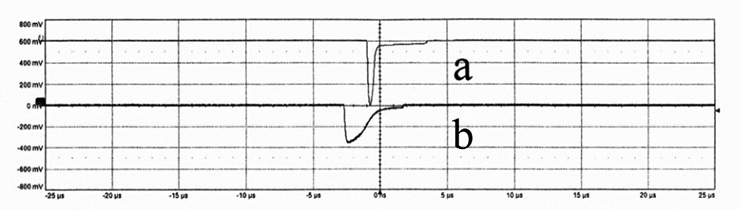

Fig. 4. Signals from two wavelength-shifting optical fibers – without defects (a) and with defects (b). The abscissa axis shows the signal duration, and the ordinate axis – the amplitude. The decrease in signal amplitude during the passage of optical waves through a damaged fiber relative to an undamaged fiber was more than 40%, and such a fiber cannot be used in a detector system

Fig. 4. Signals from two wavelength-shifting optical fibers – without defects (a) and with defects (b). The abscissa axis shows the signal duration, and the ordinate axis – the amplitude. The decrease in signal amplitude during the passage of optical waves through a damaged fiber relative to an undamaged fiber was more than 40%, and such a fiber cannot be used in a detector system

Testing of all fibers by the device is not necessary. “In general, one-time methodological work is carried out to collect statistics on a large number of fibers. It takes a week. In the future, we can detect defects using a microscope and, using these data, sort fibers out if they are unusable,” summed up Maxim Podlesnyy. He added that the device is also used for practical training of students.

On July 17, 2023, the Joint Institute for Nuclear Research was granted a patent for invention No.2800058 “Device for controlling the transmitting capacity of wavelength-shifting optical fibers”. The authors are employees of FLNP JINR Maria Petrova, Maxim Podlesnyy and Vasil Milkov.