Reinforcements/matrix micro-interface evolution and properties of in-situ Ni60A/WC coatings

News, 02 August 2024

An international team of materials scientists developed Ni60A/WC in-situ reinforced composite coatings for Inconel 718 alloy. Researchers investigated the reinforcements/matrix micro-interface evolution, microhardness, and corrosion resistance. The work was conducted in cooperation with researchers from the Laboratory of Nuclear Reactions at JINR, Jiangsu University of Science and Technology (Zhenjiang, China), and Huazhong University of Science and Technology (Wuhan, China).

The phases in the coatings are mainly composed of γ-Ni, M23C6, M7C3, and NbC. The reinforcements/matrix micro-interfaces concerned in the coatings mainly include WC/matrix micro-interface and M23C6/matrix micro-interface. The WC/matrix micro-interface evolution is divided into five stages:

- WC enters the molten pool;

- the micro-interface begins to grow;

- the reinforcements enriched at the tip;

- the reinforcements fall off;

- the formation of the stable micro-interface.

The microhardness of the coatings increases with increasing WC content. On one hand, the increase in WC content promotes the generation of in-situ reinforcements, and the large lattice mismatch between dispersed reinforcement particles and matrix hinders dislocation motion. On the other hand, the two-dimensional mismatch degree of WC and γ-matrix calculated by Bramfitt’s two-dimensional mismatch degree formula is 9.77 %, indicating that WC particles can serve as particles for γ heterogeneous nucleation. The increase of WC particles plays the role of fine grain strengthening, so the microhardness of the coating increases. The effect of WC on the corrosion resistance is also analysed. The reinforcements are mainly distributed in the grain boundaries.

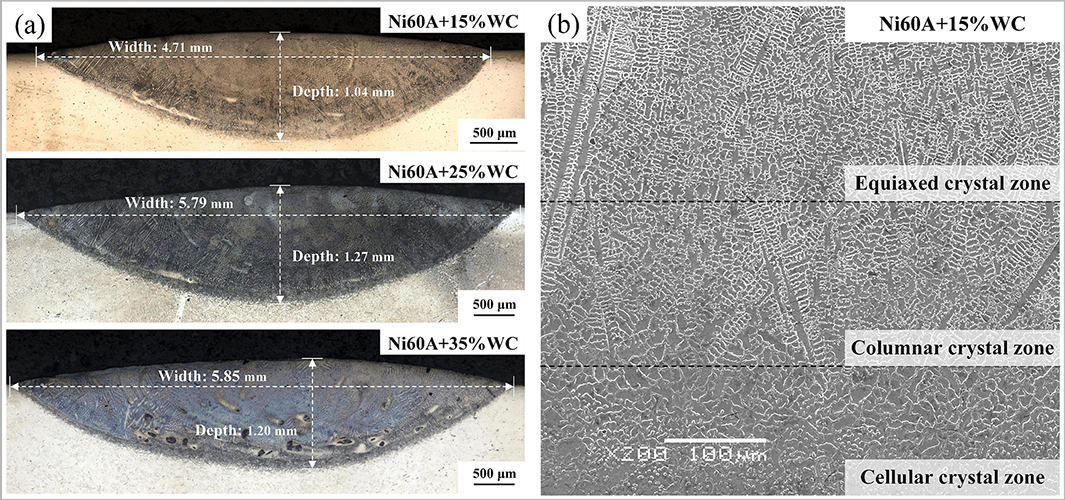

(a) Effect of WC content on forming of coatings, (b) microstructure distribution of coating (Ni60A + 15%WC)

(a) Effect of WC content on forming of coatings, (b) microstructure distribution of coating (Ni60A + 15%WC)

The HRTEM results indicate that a large degree of lattice mismatch exists in the micro-interface of reinforcements and γ-matrix. The large degree of mismatch shows that the interface between the two phases is relatively weak, and the weak interface can easily to become the channel for corrosive ion (Cl–) diffusion.

The paper entitled “Reinforcements/matrix micro-interface evolution and properties of in-situ Ni60A/WC coatings prepared by laser cladding” was issued in Surface and Coatings Technology in May 2024. Among the authors is a JINR researcher Vladimir Skuratov.